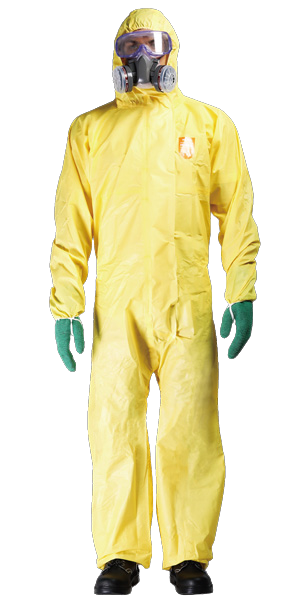

Product Description

HG6940L

The product is the lighter, thinner and more comfortable chemical protective clothing known in the market, which can meet the requirements of European Standard Type3 and Type4 standards

Close Up

Product Features

The fabric adopts a professionally proportioned polyethylene coating, which is perfectly combined with high-performance non-woven fabrics. The internal sewing and external heat-sealing process improves the seam strength, which can better protect against liquids, particles and various chemicals. Widely used in chemical industry, chemical manufacturing, synthetic materials and other fields, light and comfortable to wear

- Effectively protect a variety of liquid chemicals

- No silicone oil, no formaldehyde and other toxic and harmful substances

- Meets EN1149-5 antistatic requirements

- Meet the puncture and flame resistance tests required by the EN1073-2 standard

- The product has passed the EN14126:2003 anti-infectious medium test

- Bright yellow improves visibility and wearer’s safety Product thumb loop design prevents sleeves from slipping when arms are raised

- Widened front storm-flap with re-sealable tape, good airtightness

- The seaming adopts internal sewing and external heat sealing technology, which increases the firmness of the seam and the protective performance of the product.

- Comfortable, safe style design, and three-piece hood improve the comfort of wearing

Product Applications

Petrochemicals

Chemical manufacturing

Synthetic materials

Acid and alkali chemicals

Virus and contamination

Biochemical protection

Site survey

Industrial Cleaning Operations

Nuclear Industry Radioactive Particles and Dust Protection

Product Parameters

| Physical properties | Standard | HG6940L | Biological properties | Standard | HG6940L | |

| Wear resistance | EN ISO 12974-2/EN530 | 3 | Penetration resistant to synthetic blood | ISO 16603:2004 | 6 | |

| Bending stiffness | ISO 7854:1995 | 6 | Resistance to penetration by blood pathogens | ISO 16604:2004 | 6 | |

| Tearing | EN ISO 9073-4:1997 | 3 | Resistant to solid particle penetration | ISO 22612:2005 | 3 | |

| Stretching | EN ISO 13934-1:1999 | 2 | Resistant to liquid aerosol penetration | ISO/DIS 22611:2003 | 3 | |

| Burst | EN 863:1995 | 2 | Resistant to penetration of liquid bacteria | EN ISO 22610:2006 | 6 | |

| Ignitation | EN 13274-4:2001 | PASS | ||||

| Adhesion | EN 25978:1990 | NO | ||||

| Chemical properties | Standard | HG6940L | Whole Clothing Properties | Standard | HG6940L | |

| 30% sulfuric acid | EN ISO 6530:2005 | 3 | Inward leakage of the whole clothjing | EN ISO 13982:2004 | PASS | |

| 10% sodium hydroxide | EN ISO 6530:2005 | 3 | Whole clothing Spray Test | EN ISO 17491-4:2008 | PASS | |

| O-xylene | EN ISO 6530:2005 | 3 | Seam strength | EN ISO 13935-2:1999 | 3 | |

| Butanol | EN ISO 6530:2005 | 3 | ||||

| 30% sulfuric acid | EN ISO 6529:2001 | 6 | ||||

| 95% sulfuric acid | EN ISO 6529:2001 | 6 | ||||

| 98% sulfuric acid | EN ISO 6529:2001 | 6 | Others | Standard | HG6940L | |

| 10% sodium hydroxide | EN ISO 6529:2001 | 6 | Anti-static | EN1149-1:2006 | Pass for double sides | |

| 40% sodium hydroxide | EN ISO 6529:2001 | 6 | PH | EN ISO 3071:2006 | Pass | |

| 50% sodium hydroxide | EN ISO 6529:2001 | 6 | ||||

| 85% phosphoric acid | EN ISO 6529:2001 | 6 | ||||

| 37% hydrochloric acid | EN ISO 6529:2001 | 6 | ||||